Metri-Pack is a family of electrical connection systems that utilizes internationally standardized male blade sizes (series) allowing for flexibility in design. It was introduced in 1981 by Packard Electric (now Delphi Connection Systems), and designed to meet the assembly requirements of the automotive harness industry world-wide while providing superior electrical performance under the most severe environmental conditions

The Metri-Pack line includes many "application specific" components. Subtle terminal and housing variations within a given series are common, and most similar-looking parts are not interchangeable.

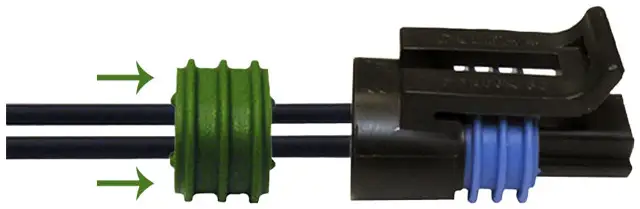

Metri-Pack is available in five different "Series" based on male terminal blade width. Each Series has specific current-carrying capacities, and each is available in both sealed and unsealed configurations. Sealed Metri-Pack uses some of the same 3-rib self-lubricating silicone rubber seal technology that has been proven with the Weather Pack connection system.

| Series | Blade Width | Current Rating |

|---|---|---|

| 150 | 1.50 mm | 14 Amps |

| 280 | 2,80 mm | 30 Amps |

| 480 | 4.80 mm | 42 Amps |

| 630 | 6.40 mm | 46 Amps |

| 800 | 8.00 mm | 60 Amps |

Unlike Weather Pack which has a “mate” for most every connector, Metri-Pack is more likely to connect to a device such as a sensor, a switch, a relay, a header block, or even an electronic control module. There are only a few in-line “mating” Metri-Pack parts.

"Pull-to-seat" (abbreviated P2S) refers to how a terminal seats or "clicks" into a connector. P2S is a sealed connector design that uses a common multi-wire rear connector seal instead of individual cable seals on each terminal. A P2S terminal is crimped onto a wire which is then drawn backwards into the connector body through the front of the connector. The locking "tab" (or "spur" or "detent") is oriented backwards compared to the common push-to-seat terminals. Pull-to-seat is most common with sealed Metri-Pack 150 connectors designed to fit sensors, switches, or modules. Here's how they are assembled:

Pull leads backword through the front of the connector until the terminas click into place.

Feed lead ends through cable seal, and slide seal all the way into the back of the connector.

You may want to order terminal picks such as our T-5 or T-6 in case you need to disassemble a completed Metri-Pack termination for inspection or rework.

Not necessarily. Many open barrel crimp tools can perform acceptable Metri-Pack terminal and seal crimps. A number of suitable tools are shown on our tool site, www.terminaltools.com. Please note that we cannot guarantee that a given tool will perform a satisfactory crimp on a specific Metri-Pack terminal due to variables that include terminal material, terminal wall thickness, wire gauge, wire stranding, and wire insulation thickness. The user must make the final determination that a crimp is acceptable.

The choice of cable seal is determined by the insulation diameter of the wire being used. The guidelines offered below apply to Weather Pack and Sealed Metri-Pack 280 Series installations.

For Type GPT and GXL wire, the red seal normally fits 22 gauge; the green seal normally fits 20, 18, and 16 gauge; the gray seal normally fits 14 gauge; and the blue seal normally fits 12 gauge.

For heavier wall Type SXL wire, the green seal normally fits 20 and 18 gauge; the gray seal normally fits 16 gauge; and the blue seal normally fits 14 and 12 gauge.

For thin-wall wire construction such as Type TXL, the red seal normally fits 20 gauge; the green seal normally fits 18, 16 and 14 gauge; the gray seal normally fits 12 gauge; and the blue seal normally fits 10 gauge.

The installer must be certain that the seal fits snugly over the wire insulation to maintain a proper environmental seal.

Click the “Online Catalog” button and navigate to the Useful Information page for primary wire insulation diameters and more Delphi cable seal application information.

The Metri-Pack system uses only flat male blade terminals and “box” profile female terminals. They might be Weather Pack components or parts from another manufacturer.

This marking identifies the connector material Polyamide 6/6 (a.k.a. nylon) and the mold cavity number. This is not enough information to identify a component. Delphi/Packard Electric Systems' part numbers are typically 8 digits such as "12129493."

The Metri-Pack line includes hundreds of parts designed for OEM use that have minimal aftermarket demand. Instead of stocking everything, we carry larger inventories of the popular Metri-Pack components that are of interest to our customers.

Metri-Pack terminals are included in the service kit assortments that must be stocked by all General Motors dealerships.

Our sealed Metri-Pack connector kits are sold in quantities as small as "one." Purchasing a single kit may be the least expensive and most convenient way to obtain needed parts in very small quantities. Unused components can be discarded or saved for future use.

We are often able to identify components from digital photographs. If you eMail clear images, front and rear, to sales@whiteproducts.com, we may be able to identify the component and provide the OEM part number.